Comprehensive Metal Shaping and Processing Solutions

Integrated Approaches to Custom Metal Processing #

Jinholly offers a wide spectrum of metal shaping and processing services, designed to meet the evolving needs of clients across various industries. With over two decades of manufacturing experience, we focus on delivering efficient, high-quality, and cost-effective solutions through process integration and professional evaluation.

Our Core Processing Services #

- Powder Metallurgy: Ideal for producing complex parts with high dimensional accuracy and material utilization. Powder metallurgy allows for tailored material compositions and the creation of shapes not achievable by traditional cutting processes.

- Lost Wax Casting: Suitable for components with intricate shapes and high strength requirements. This method reduces manufacturing steps, minimizes material waste, and offers flexibility in material selection, resulting in shorter lead times and lower costs.

- Forging Processing: Alloy forgings are heated and shaped under pressure, yielding parts with excellent mechanical properties such as directional strength, impact resistance, and fatigue resistance.

- Aluminum Alloy Processing: We provide aluminum alloy machining services, including heat and surface treatments, to achieve optimal strength, impact resistance, and fatigue resistance according to client specifications.

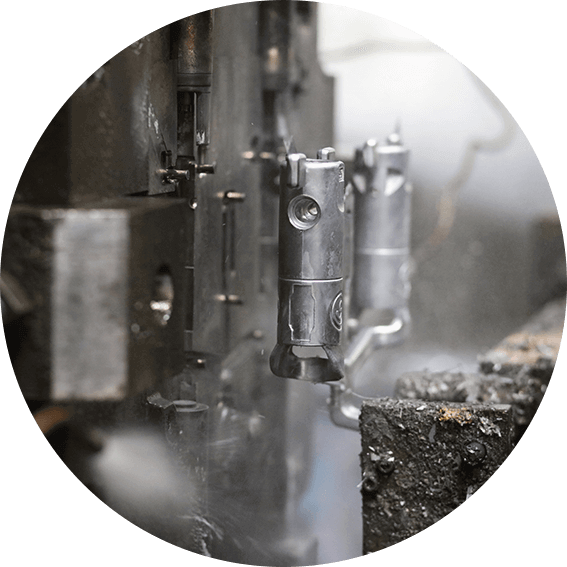

- Metal Injection Molding (MIM): MIM combines powder metallurgy and injection molding, overcoming the limitations of traditional methods in terms of shape complexity, strength, and production efficiency.

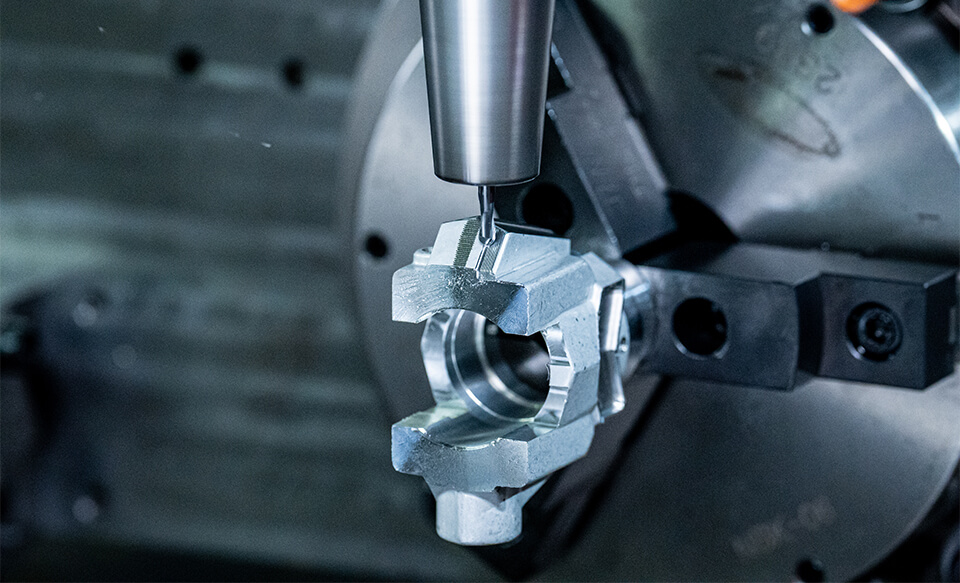

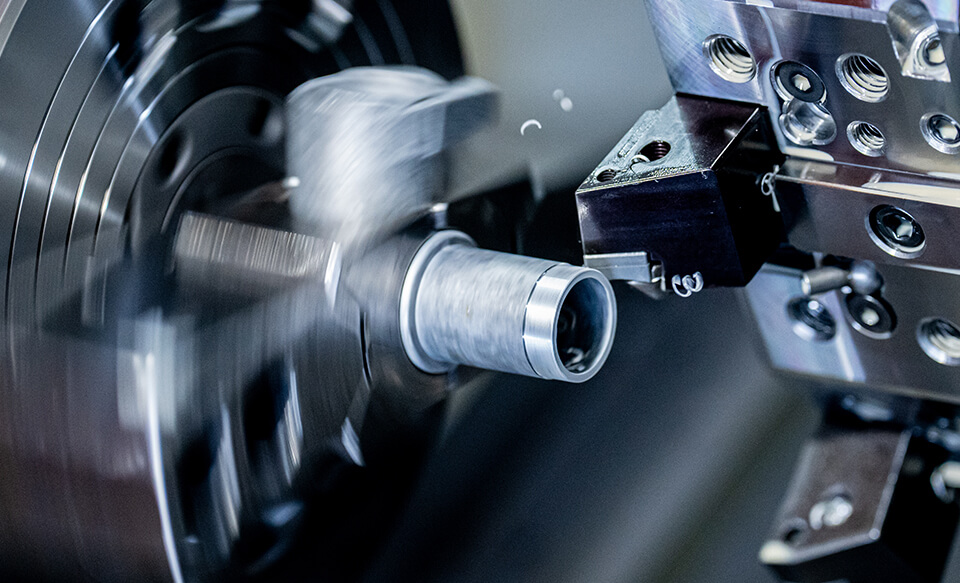

- CNC Milling and Turning: Our team designs custom fixtures and precisely controls tolerances, executing machining processes based on client drawings or samples.

CNC Turning and Milling Service

CNC Turning and Milling Service

Lost Wax Casting

Lost Wax Casting

Aluminum Alloy Processing

Aluminum Alloy Processing

Metal Forging

Metal Forging

Metal Injection Molding

Metal Injection Molding

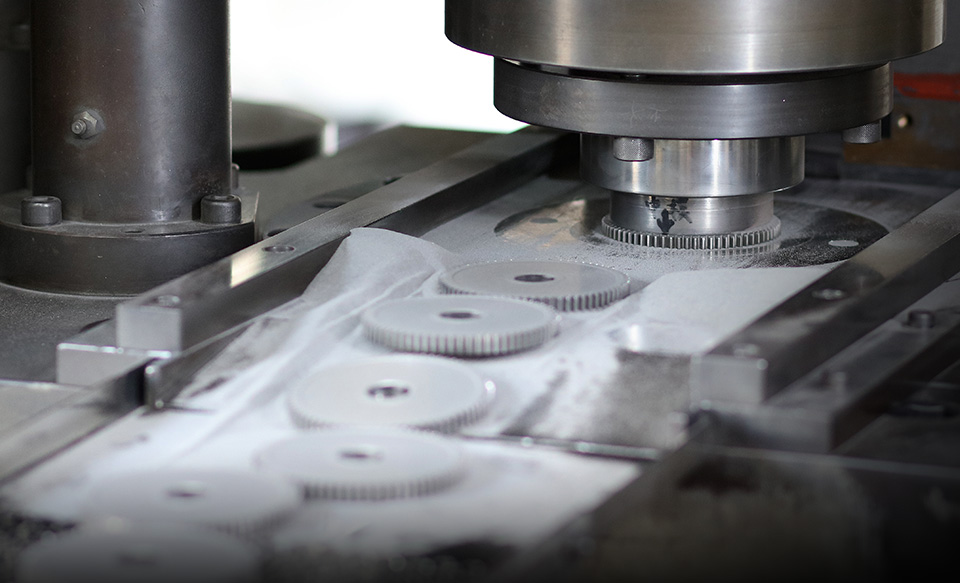

Powder Metallurgy

Powder Metallurgy

Why Choose Jinholly? #

Jinholly is recognized for its commitment to professional and safe services, with a focus on process integration. Our vertically integrated, one-stop solutions span the entire production chain, from raw materials to finished products. This approach helps clients reduce costs, streamline operations, and achieve high efficiency and quality.

- Customized Design Solutions: We evaluate various construction methods to provide tailored solutions for each project.

- Professional Process Integration: By integrating upstream and downstream processes, we ensure seamless production and consistent quality.

- Diverse Industry Applications: Our expertise covers a broad range of fields, adapting to the unique requirements of each client.

Additional and Secondary Processing #

Beyond primary manufacturing, Jinholly offers a range of secondary processing services, including:

- CNC milling and turning

- Surface treatment

- Heat treatment

These services are designed to meet diverse customer requirements and enhance the value of finished products.

Tailored Solutions and OEM/ODM Services #

Jinholly provides professional and competitive solutions by selecting the most appropriate processing methods for each client. Through resource integration and comprehensive data and cost analysis, we help clients create products with higher value, reduced costs, and improved efficiency.

For more information or to discuss your project needs, please contact us.