Comprehensive Metal Processing Solutions for Diverse Industries

Table of Contents

Comprehensive Metal Processing Solutions for Diverse Industries #

Jinholly Co., Ltd. is committed to delivering high-quality metal machining and processing services from our advanced facility in Taiwan. With a focus on precision, efficiency, and flexibility, we support clients worldwide with both OEM and custom metal shaping solutions tailored to a variety of industrial needs.

Our expertise spans the entire production cycle—from raw materials to finished or semi-finished products—enabling us to optimize manufacturing processes, reduce lead times, and minimize transportation costs. In addition to core machining, we offer supplementary services such as surface and heat treatments, ensuring that every product meets stringent quality standards and client specifications.

Powder Metallurgy

Powder Metallurgy

Lost Wax Casting

Lost Wax Casting

Forging Processing

Forging Processing

Aluminum Alloy Processing

Aluminum Alloy Processing

Metal Injection Molding

Metal Injection Molding

Metal Stamping

Metal Stamping

Our Core Metal Processing Services #

Powder Metallurgy #

Powder metallurgy involves mixing and pressing metal powders, followed by sintering to achieve the desired mechanical properties. Post-sintering, components may undergo machining, heat, and surface treatments. This method is ideal for producing auto parts, hand tool components, sewing machine parts, power and pneumatic tool parts, pulleys, gears, woodworking machine parts, locking mechanisms, and self-lubricating bearings.

Lost Wax Casting #

Lost wax casting allows for intricate product designs by carving wax models, which are then replaced by metal through casting. The process accommodates a wide range of materials, including stainless steel, carbon and alloy steels, low-alloy steels, aluminum alloys, and tool steels.

Forging Processing #

Forging can be performed as hot, cold, or warm forging. This technique enhances the physical properties, strength, and toughness of metals, and is suitable for parts with specialized shapes. Utilizing CNC lathes and advanced equipment, we ensure precise control over dimensions and product quality.

Aluminum Alloy Processing #

Aluminum alloy products are valued for their lightweight nature. Depending on application requirements, materials of varying hardness are selected to ensure durability and strength. Manufacturing methods include extrusion, casting, gravity casting, and forging, tailored to the desired appearance and size.

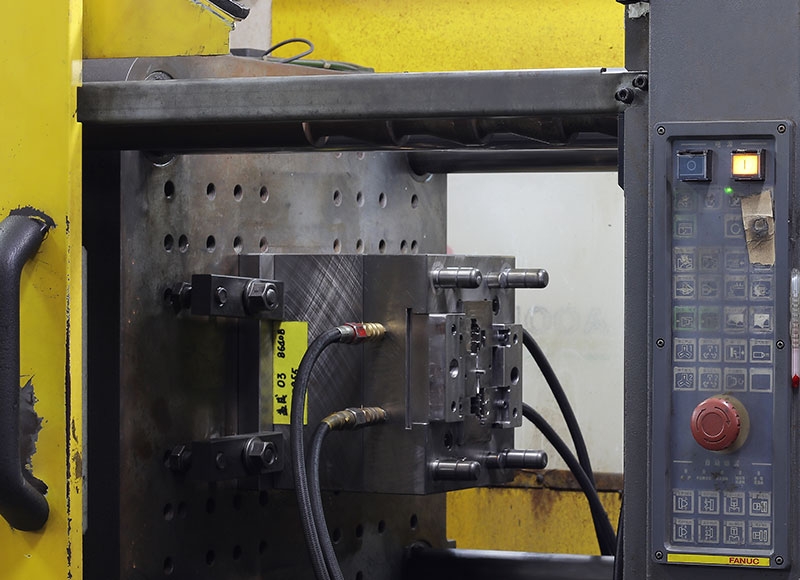

Metal Injection Molding (MIM) #

MIM is ideal for producing small, complex components with high dimensional accuracy and toughness, reducing the need for secondary machining and minimizing material waste. Applications include computer and electronic parts, medical devices, automotive components, bicycle gears, hand and power tool parts, sewing machine parts, locks, photocopier parts, and drive shafts.

Metal Stamping #

Metal stamping utilizes punches or specialized machines to shape and compress materials, resulting in lightweight, rigid products with consistent quality. This process also supports efficient material reuse and recovery.

OEM / ODM Solutions #

We assist clients in selecting the most suitable processing methods to reduce costs, enhance efficiency, and ensure high-quality outcomes. Our team is ready to provide tailored solutions for your unique project requirements.

For more information or to discuss your project needs, please contact us.