Innovative Solutions for Complex Metal Components #

Metal injection molding (MIM) is a sophisticated manufacturing process designed for producing small, intricate metal parts with high dimensional accuracy and excellent mechanical properties. At Jinholly, we leverage over two decades of experience and advanced equipment to deliver reliable, high-quality MIM solutions tailored to diverse industry needs.

Comprehensive Capabilities in Metal Injection Molding #

Our facility is equipped with high-performance injection molding machines and specialized molds, enabling us to significantly enhance production efficiency and maintain consistent quality. Post-molding, we utilize CNC lathes and milling machines to further refine components, ensuring precise dimensions and meeting specific client requirements. Our expertise extends to a range of secondary processes, including shaping, drilling, reaming, tapping, grinding, and turning, allowing us to address even the most demanding manufacturing challenges.

Key Advantages of Metal Injection Molding #

- Efficient Mass Production: Mold-based forming is ideal for large-scale manufacturing, reducing lead times and costs.

- Superior Material Properties: MIM parts exhibit strong mechanical strength, high toughness, and material diversity.

- Complex Geometries: Our process accommodates intricate shapes, minimizing the need for additional machining and reducing material waste.

Application Versatility #

Metal injection molding is particularly suited for components requiring small size, complex geometry, high density, and excellent surface finish. Our MIM products are widely used in:

- 3C electronic parts

- Medical devices

- Automotive and motorcycle components

- Bicycle gears

- Hand and power tool parts

- Pneumatic tools

- Sewing machine parts

- Locks and lock cores

- Office machine components

- Drive shafts

Technical Expertise and Quality Assurance #

MIM production involves careful consideration of factors such as mold precision, sintering stability, and potential shape deformation. Our team conducts thorough evaluations at every stage to ensure optimal outcomes. By integrating advanced technology with stringent quality control, we consistently meet the highest industry standards and deliver solutions for even the most challenging material tolerances and dimensional requirements.

Commitment to Client Success #

With a focus on continuous improvement and technical innovation, Jinholly is dedicated to supporting clients throughout the product development cycle. We offer both OEM and ODM solutions, selecting the most appropriate processing methods to help clients reduce costs, achieve high efficiency, and receive exceptional service.

For inquiries or to discuss your project needs, contact Jinholly.

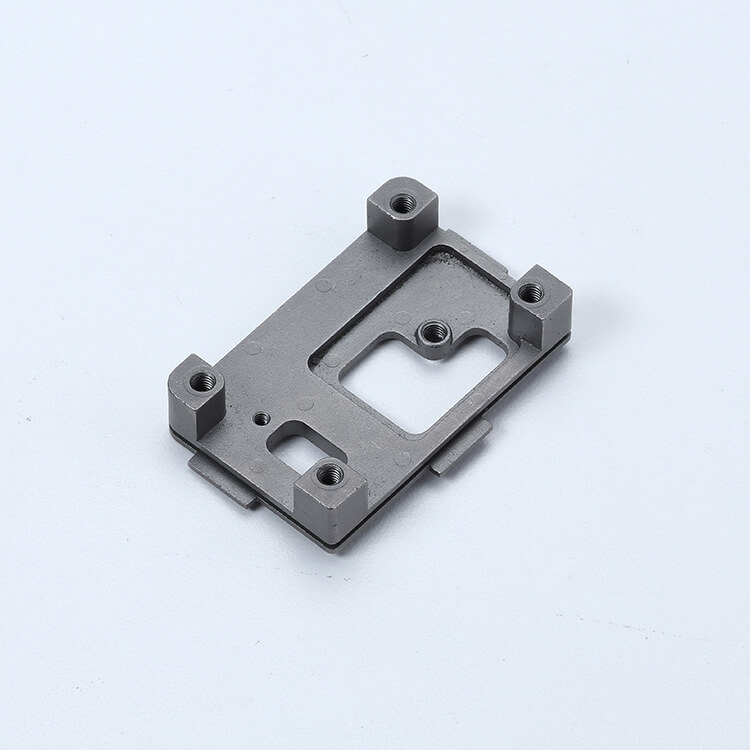

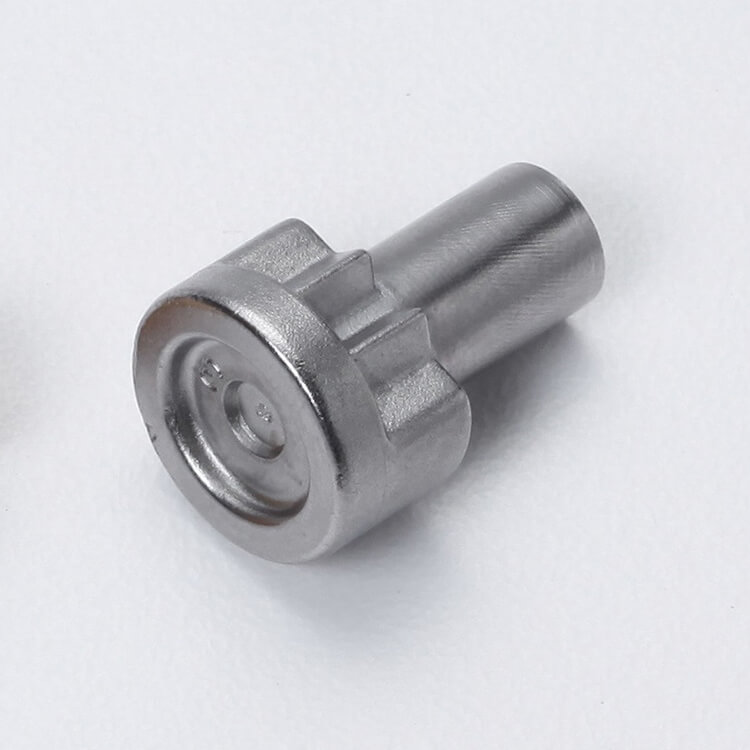

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Customized Products

Global Collaboration #

We welcome partners and buyers from around the world to visit our facility and explore opportunities for cooperation. For more information or to start your next project, contact us.